Piecing together our masterpiece!

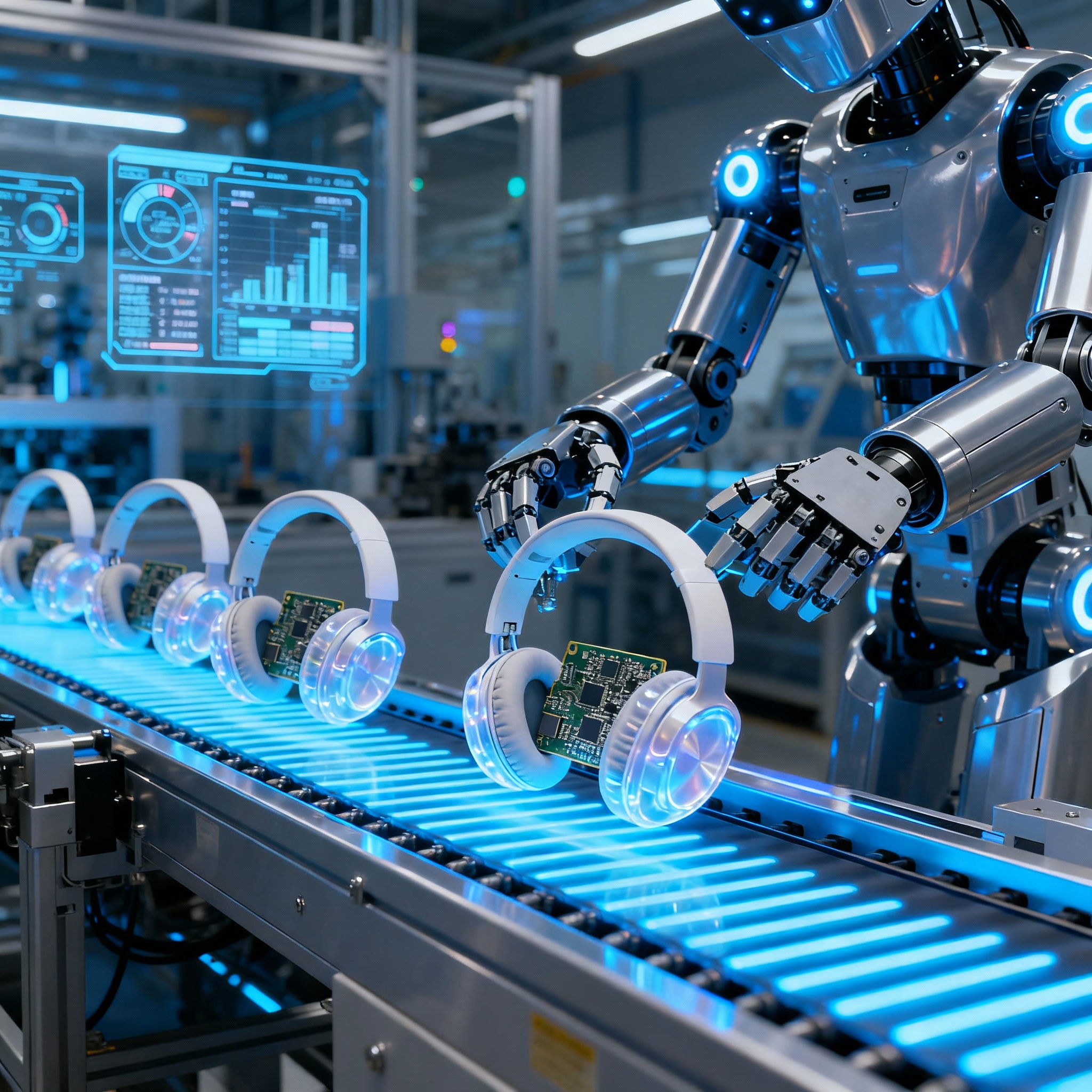

From concept to reality: Privatone is hard at work building both the software and the hardware components for our launch product, the Model H1. As we near hardware prototyping, we need to understand what our ultimate and cost-effective path to production will be.

3D prototyping and OEM (Original Equipment Manufacturer) or white-label manufacturing are critical steps for startups aiming to bring consumer electronic devices, such as headsets, to market. Particularly in China, these services are well-established and offer a streamlined pathway from concept to mass production, but they involve specific requirements, processes, costs, and timelines that are vital for a start-up’s planning.

The 3D Prototyping Process

3D prototyping involves creating a tangible model of the device design to evaluate form, fit, and function before moving to mass production. It typically begins with detailed CAD (Computer-Aided Design) files, which are then used to produce prototypes using 3D printing or CNC machining. These prototypes help refine product aesthetics, ergonomics, and internal layout.

OEM and White-Label Manufacturing

OEM manufacturing refers to producing devices based on a company’s specifications, which can include branding, features, and design nuances. White-label manufacturing is similar but often involves standardized products that can be rebranded and customized minimally. In China, numerous factories and service providers specialize in electronics OEM, offering capabilities for headset assembly, electronics integration, and finishing.

Requirements and Process

To engage in OEM or white-label manufacturing, startups typically need:

- Detailed CAD/Engineering files

- Clear specifications and Bill of Materials (BOM)

- Quality standards and certifications (e.g., CE, FCC)

- NDA and intellectual property agreements

The process generally involves:

- Concept and design finalization

- Prototype development and testing

- Pilot production runs

- Quality assurance and certification

- Full-scale manufacturing

Costs and Timelines

Costs vary widely depending on complexity, volume, and quality requirements. A basic prototype might cost between $1,000–$5,000 for initial development, while small batch production (100–1,000 units) can range from $10,000 to $50,000. Lead times typically span from 4 to 12 weeks for prototypes, and mass production can take an additional 8–16 weeks, depending on the scope and certification needs.

Popular Service Providers

Several well-known China-based manufacturers and services cater to startups:

- Santa Barbara Polymers – specializing in electronics and consumer devices

- Shenzhen Topwise – offering OEM manufacturing with rapid prototyping

- Pioneer Electronics Manufacturing – providing turnkey solutions

- Jabil and Flex – large-scale manufacturers with extensive OEM services

These providers often feature integrated R&D, prototyping, and mass production capabilities, accommodating startups with varying needs.

How It Fits into a Startup Business Model

For startups, leveraging Chinese OEM services can significantly reduce time to market and up-front investment. It enables rapid iteration through prototypes and small-batch runs, testing market demand without large capital expenditure. The key is to balance design innovation with strict quality control and an understanding of intellectual property rights.

By partnering with experienced OEM providers, startups can focus on branding, marketing, and user experience while leaving manufacturing complexities to established factories. When scaled efficiently, this approach offers a flexible and cost-effective route to launch hardware products like headsets in a competitive consumer electronics landscape.